Fiber Reinforcement In 3D Printing With Clay

OTF 2019/2020

Faculty: Alexandre Dubor, Edouard Cabay, Kunaljit Singh Chadha Assistant: Ashkan Foroughi Dehnavi

Students: Jae Shin, Angelika Bocian

About 30 percent of the world’s population (1.5 billion people) live in earth house. Most earth houses are located in earthquake area so traditional earthquake resistant method were developed. However, 3d earth printing technology has not enough reinforcement way for earthquake resistance, and also for taller buildings, more complex geometry and bigger cantilever angles. This research is for finding reinforcement way of 3d earth printing house.

The reinforcement of 3d earth printing can be categorized in 3 scales. Micro scale is short fiber (less than 1cm) mixed with clay. Macro scale is reinforcement between layers. In this scale, anisotropy should be considered because 3d printing has different strength depends on direction. Global scale is how to reinforce with geometries such as wall, cantilever and arch. So this research follows these 3 scales.

In Micro and Macro scale, 3d printed samples were tested in Wet condition and Dry condition. Wet condition is for stability in construction. Dry condition is testing improvement strength of 3d earth printing. For testing dried samples, three-points flextural test was used by crash machine. By this test, we can calculate tensile force of samples. By this testing, placing wood frame in 3d printing layers has the best result. But pre-tensioned rope has more potential for design freedom.So we decided to use micro fiber + fibers inmixed (second result) and pre-tensioned rope (third result).

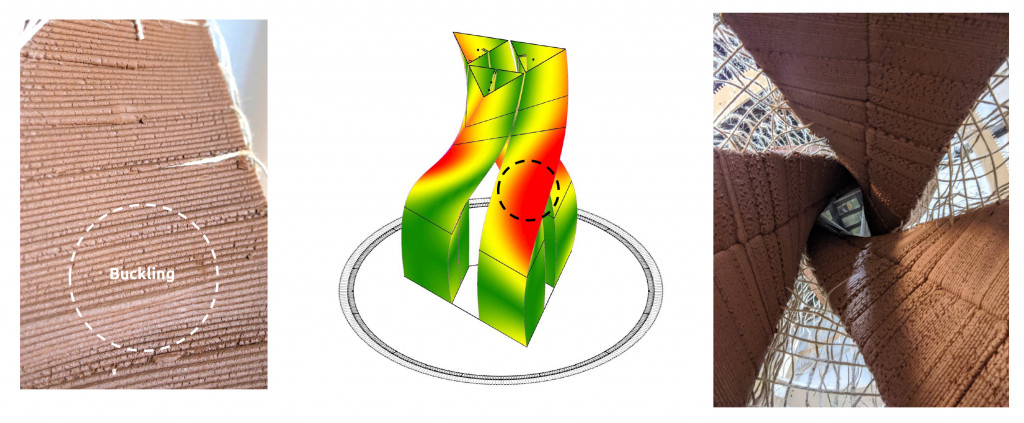

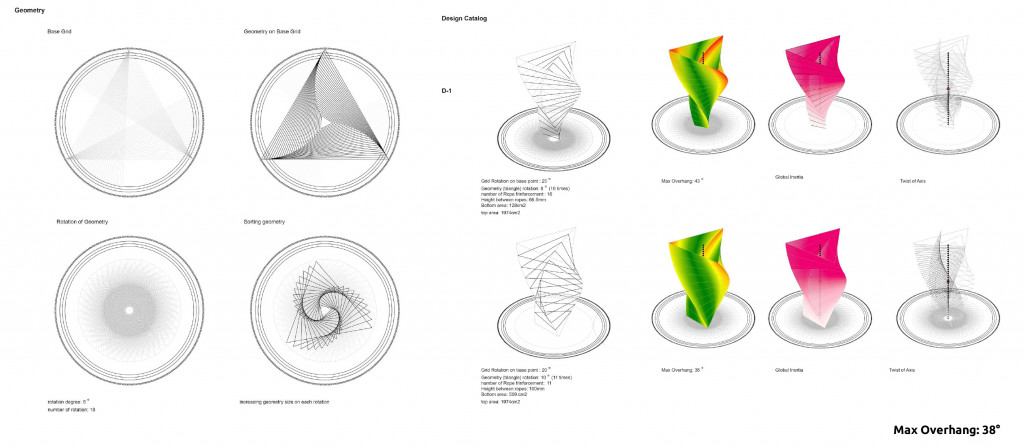

This geometry was produced based on 326 ropes grid. It has 40 degree overhang and 120 degree rotation. It is stated to be printed in 3 separate triangles and these are combined in 800 mm height with twisting. Structure Analysis shows bending possibility on the edges and each triangle’s CG(center of gravity) point is located outside of base triangle. Global CG point are located in center opening so it is three column arch. Without reinforcement, it is not possible to be printed.

Printing was successful. This column reached 1.2 m without infills and was quite stable. We could find 3 conclusions in this testing

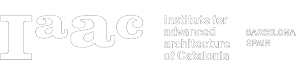

1_Rope was placed in every 10 layers. On 7-8th layer, buckling was found but after placing rope on 10th layer, buckling became 0. Usually, buckling starts from lower layer slightly but it becomes severe in higher layer. This rope reinforcement distributes buckling to small portion (In this test rope distributes bucking every 10 layers). So more risky geometry can be printed in stable condition.

2_Weak points in Digital structure analysis and real printing coincide. So in next step, we can abstract place of reinforcement by structure analysis and reducing rope number.

3_Ropes which connect three columns are also helpful to stabilize whole geometry. These rope keep tension during printing so each column holding the other columns. This will make more safe construction.

Adapting 3d earth printing technology through reinforcement for earthquake resistance, taller buildings, complex geometries and bigger overhang.